Servizio

Esperienza e tecnologia,

dal vostro progetto al componente finito.

La nostra profonda competenza unita alla tecnologia più evoluta.

Un processo ottimizzato e monitorato in ogni sua fase.

Il servizio completo, dal vostro progetto 3D

al componente in zama o alluminio finito e confezionato.

Pressofusione

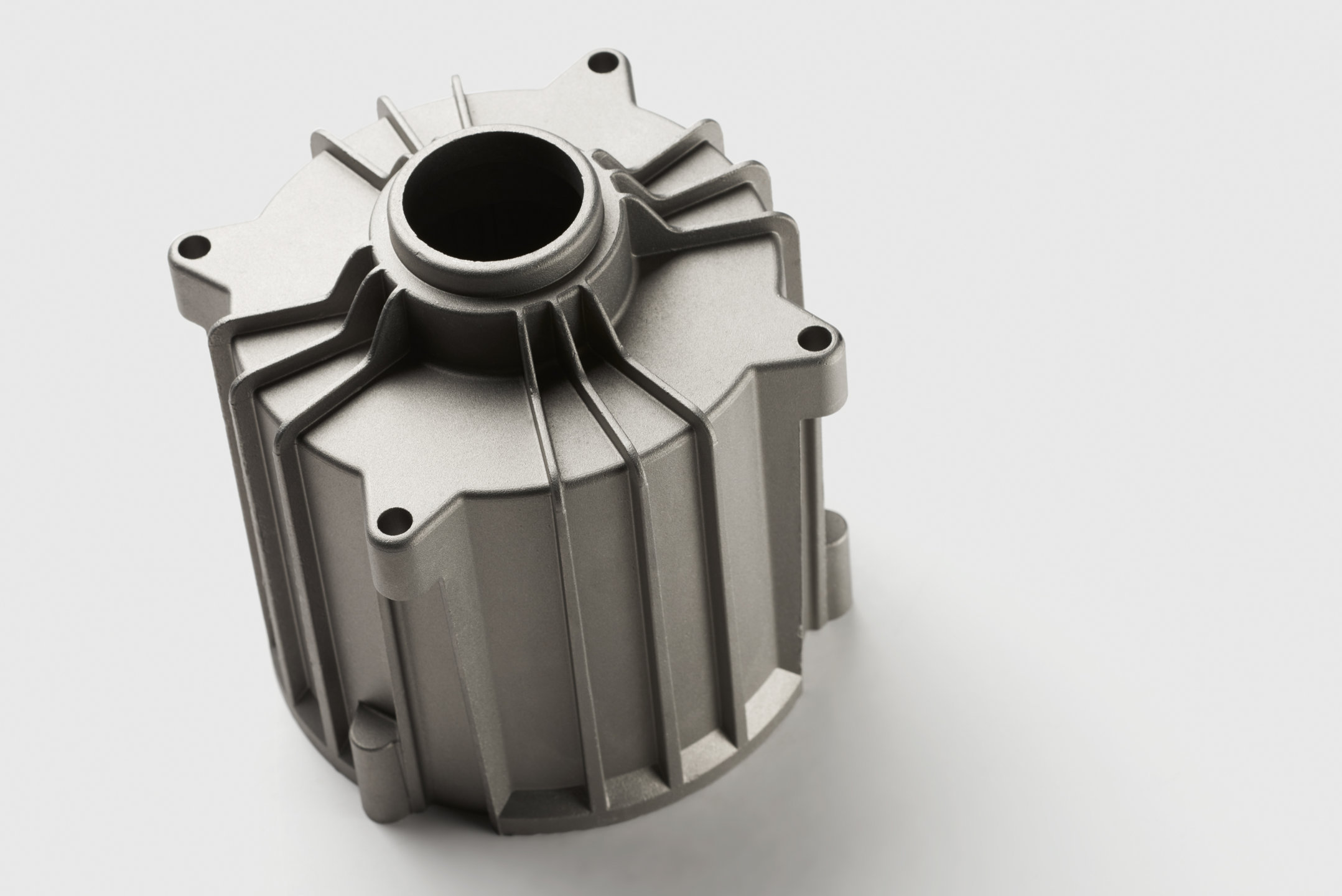

Alluminio

Per rispondere alle esigenze della propria clientela, dal 2017 l’azienda ha integrato il suo parco macchine con una nuovissima isola di lavoro robotizzata della potenza di 550 TON per la pressofusione dell’alluminio

Pressofusione

Zama

Un processo ottimizzato e monitorato in ogni sua fase.

Il servizio completo, dal vostro progetto 3D

al componente in zama o alluminio finito e confezionato.

Progettazione e costruzione

Stampi

Punto di forza della FP Cupido è la propria attrezzeria, nata per la semplice manutenzione di stampi ed attrezzature interne, ed evoluta nel tempo in una vera e propria officina meccanica per costruzione stampi.

Pulitura

Metalli

Da più di 20 anni la FP CUPIDO dispone, nel proprio interno, di reparti completamente autonomi di pulitura metalli, eseguendo lavorazioni di smerigliatura, burattatura, barilatura e granigliatura di ogni genere.

Certificazioni

Sostenibilità

Contatta l’azienda

Per ricevere ulteriori informazioni sui nostri servizi e prodotti o per essere contattati da un nostro commerciale potete compilare il seguente modulo. È nostra premura rispondervi nel più breve tempo possibile per approfondire gli argomenti di vostro interesse.